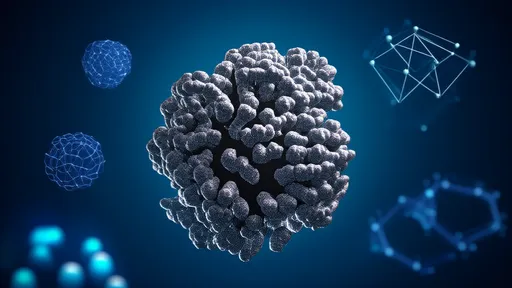

In the high-stakes race to develop faster, cleaner chemical processes, scientists are turning to one of the most bizarre phenomena in quantum physics. A new class of materials called topological quantum catalysts is rewriting the rules of catalysis by harnessing exotic electron behaviors that occur at the atomic scale. These peculiar electronic states – long studied in theoretical physics – are now demonstrating an uncanny ability to accelerate industrial reactions while resisting degradation.

The breakthrough comes from applying principles of topological quantum materials to traditional catalyst design. Where conventional catalysts rely on surface chemistry, these new materials exploit protected electron states that emerge from the material's unique geometric structure at the quantum level. "It's like discovering your car's engine runs better when the pistons move in four dimensions instead of three," quipped Dr. Elena Vescovi, a materials scientist at the Max Planck Institute who recently published groundbreaking work on bismuth-based topological catalysts.

What makes these materials so revolutionary is their combination of robustness and reactivity. The topological protection of their electronic states means the active sites resist poisoning and degradation – the bane of traditional catalysts. Yet simultaneously, their peculiar electron configurations create "quantum hot spots" with extraordinary ability to lower activation barriers for key reactions. Early demonstrations show order-of-magnitude improvements in hydrogen production and carbon dioxide conversion.

The Quantum Advantage in Catalysis

At the heart of these materials lies a quantum phenomenon called spin-momentum locking, where an electron's spin becomes tied to its direction of motion. This creates surface states that are remarkably resistant to disturbances while maintaining exceptional chemical activity. Unlike traditional catalysts where surface defects often deactivate sites, the topological protection ensures these quantum states persist even in imperfect real-world conditions.

Researchers at Stanford recently demonstrated this resilience by deliberately introducing impurities into a tungsten telluride topological catalyst. While conventional platinum catalysts showed immediate performance drops, the topological material maintained over 90% of its activity after contamination that would have killed other catalysts. "It's as if the reaction sites exist in a protective quantum bubble," explained lead researcher Professor Mark Hersam.

Industrial chemists are particularly excited about applications in sustainable chemistry. The unique electron configurations appear ideally suited for activating stubborn small molecules like N₂ and CO₂. BASF's catalysis division has already begun prototyping reactors using topological catalysts for ammonia synthesis, potentially revolutionizing the energy-intensive Haber-Bosch process that feeds half the world's population.

From Lab Curiosity to Industrial Reality

Just five years ago, topological materials were laboratory curiosities studied mainly for their bizarre physics. The pivot toward practical applications began when researchers noticed unexpected catalytic activity in materials like bismuth selenide during unrelated quantum computing experiments. "We were trying to build qubits and accidentally made a better catalyst," recalls Dr. Hiroshi Takayama of RIKEN, whose team published the first observation of this effect.

The field has since exploded, with over twenty major research groups now developing topological catalysts. Recent advances include hybrid materials that combine topological protection with traditional catalytic metals, creating "quantum-amplified" systems. MIT's nanotechnology lab recently created a platinum-topological insulator composite that shows both the high activity of precious metals and the durability of topological materials.

Scaling up production remains challenging. These materials often require atomic-level precision in their crystal structures to maintain their quantum properties. Startups like Quantum Catalytix are developing novel vapor deposition techniques to grow topological catalyst films on industrial-scale substrates. "It's like trying to grow a perfect crystal while riding a rollercoaster," admits CEO Dr. Samantha Wu, whose company recently secured $40 million in Series B funding.

The Future of Quantum-Enhanced Chemistry

As research progresses, scientists are discovering that topological effects may explain long-standing mysteries in catalysis. Some theorize that many conventional catalysts may have unknowingly benefited from nanoscale topological features. A recent re-examination of industrial nickel catalysts revealed previously unnoticed topological surface states that could account for their exceptional performance.

The next frontier involves designing topological properties to target specific reactions. Researchers at ETH Zurich are using machine learning to predict which exotic material combinations might create ideal quantum states for breaking particular chemical bonds. Their algorithms recently identified a promising zirconium-based topological catalyst for methane conversion that's now being tested by Shell.

With the first commercial applications expected within 3-5 years, topological quantum catalysts represent a rare example of abstract quantum physics delivering immediate practical benefits. As the field matures, it may fundamentally change how we design chemical processes – making reactions faster, cleaner and more energy efficient by harnessing the strange rules of the quantum world.

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 10, 2025

By /Jul 10, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 9, 2025